|

|

||||||||||||||||||||||

|

Chemical and Process Engineering |

||||||||||||||||||||||

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|||||||||||||||||

|

A S Jessup-Bould: Sludge Drying |

||||||||||||||||||||||

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

Client: MCUA; New Jersey, USA |

||||||||||||||||||

|

2000 / 2001 |

Services provided to CPL Biomass for the front end process design for of a facility for the partial drying of sludge. |

|||||||||||||||||||||

|

2004 / 2006 |

Services provided to R3m inc for detailed design review and technical support for during installation. |

|||||||||||||||||||||

|

|

|

|

|

|

|

|||||||||||||||||

|

Project Summary |

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|||||||||||||||||

|

In 2000 CPL Biomass were contracted

by R3m Limited to design a 5 stream sewage sludge partial drying

plant as part of MCUA’s (Middlesex County Utilities Authority) modifications

to its existing land-based residuals management facilities at the Edward J

Patten Water Reclamation Facility in Sayerville,

New Jersey, USA. The

purpose of the drying process is to condition the sludge for a new

pasteurization plant which replaces a pre-existing curing process. Following

a disruption to the contract, the sister company R3M inc finished building the plant in 2006. In July 2004, as

part of this work, Jessup-Bould Limited was engaged

by R3m to provide engineering and consultancy services. |

|

Courtesy MCUA |

||||||||||||||||||||

|

Courtesy

R3m |

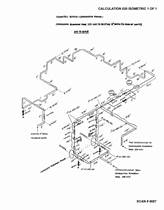

During this contract JBL

undertook the following tasks: ·

The

production of a set of final design calculations. ·

Generated

a design basis report for the thin film dryers and support services. ·

Provided equipment and process design reviews

for the drying plant and its peripherals. ·

Where variations from the original conceptual

design or other concerns were found they were raised and discussed with R3m.

·

Advised Client of recommendations and

modification requirements; for example; valve fail positions, locking of

valves, pump impeller de-rating, operational techniques to minimise fouling,

personnel training, dryer blade configuration record keeping (for

maintenance) |

|||||||||||||||||||||

|

|

|

|||||||||||||||||||||

|

|

||||||||||||||||||||||

|

Process Description |

||||||||||||||||||||||

|

|

||||||||||||||||||||||

|

The sludge treatment plant dries raw

primary liquid sludge to produce a dried cake product suitable for mixing

with lime for use as a composting additive.

It is designed to operate under automatic control 24 hours per day,

8000 hours per year treating raw undigested sewage sludge from Middlesex County

Utilities Authority sewage treatment works. There are five drying streams, 3 of

which operate for one half the year and 4 for the other half. A fifth stream

is a standby. Sludge

cake from the dewatering building is fed to five wet cake silos via duty /

standby drag link type conveyors. Each silo serves a dedicated drying stream

as follows: A

hydraulically driven discharge device that moves across the flat floor of the

silo pushing sludge into the single discharge screw at the base of the silo.

The variable speed discharge screw transports the sludge cake via a chute

into the feed hopper of the progressive cavity wet cake pump. Sludge

cake is fed at a set rate, to the thin film dryer. The dryer is a thermal fluid jacketed,

horizontally mounted, cylindrical vessel within which there is an unheated

rotor with rows of stainless steel blades. Turning of the rotor spreads the

incoming sludge cake in a thin film over the heating surface and transport

the material through the unit while maintaining it in contact with the

heating surfaces. The retention time of the sludge in the thin film dryer is

sufficient to achieve a solids dryness of 55-60% and provide good pathogen

kill. Dried

sludge falls from the end of the thin film dryer on to one of two enclosed

belt type conveyors for transfer to the Pasteurization section of the plant. Odorous

air from the Pasteurizer air manifold enters the dried product discharge end

of the dryer. The air and water vapour driven from the sludge leaves the

vapour hood located at the wet sludge inlet end of the dryer. This provides

counter-current flow for optimum drying and capture, by the wet solids of

dust from the odorous air. In the event of an emergency

shut-down, a pressurised water spray system is activated to cool and rewet

the sludge thus generating steam to provide an inertising

atmosphere inside the dryer to minimise the risk of dust explosion. |

||||||||||||||||||||||

|

The air and water vapours from the

dryer are drawn into a vapour condenser by the vapour fan, which

automatically maintains a slight vacuum condition within the thin film dryer

and thus slightly enhances the evaporation rate of water from the sludge and

avoids leakage of dust. Recirculating condensate cooled in a duty / standby

plate heat exchanger is used as the coolant in the vapour condenser. Filtered

final effluent is the cooling medium in the plate heat exchangers. The non-condensable vapours drawn

from the top of the vapour condenser by the vapour fan,

are sent to a common thermal oxidiser. A droplet separator is installed prior

to the fan. In order to prevent excessive

cooling of the condensate in the plate heat exchangers and hence minimise the

possibility of fouling by fatty deposits, the return temperature of the

condensate is controlled by automatically adjusting the flow rate of final

effluent through the plate heat exchangers. Excess condensate is pumped to a

common condensate blow-down tank. Each

dryer has a dedicated thermal fluid heating and distribution system to

provide the heat for sludge drying. The thermal fluid heater has a fully

modulating burner suitable for burning landfill gas, natural gas or gas oil. A thermal fluid cooler is provided for

emergency shutdown use to prevent the sludge in the dryer from being

over-heated or over-dried. Odorous air discharged from the five

drying streams is treated by a thermal oxidizer, along with odors from the wet cake silos. |

Courtesy MCUA |

|||||||||||||||||||||

|

|

|

|||||||||||||||||||||

|

Specific

Responsibilities |

|

|||||||||||||||||||||

|

|

|

|||||||||||||||||||||

|

|

|

|||||||||||||||||||||

|

|

|

|||||||||||||||||||||

|

|

|

|||||||||||||||||||||

|

Equipment Silos Progressive

cavity pumps Thin

film dryers Direct

contact vapour condensers Thermal

fluid heating system Regenerative

thermal oxidizer Plate

heat exchangers, shell and tube heat exchangers Centrifugal

pumps, fans Materials

of Construction Mainly

stainless steel. |

Hazards Potentially

explosive dust. Pathogenic

material. Hot

thermal fluid. Liaison Client

and plant Owner. Equipment

vendors. Documents

Produced Basis

of design. Material

& energy balances. P&IDs. Process

data sheets. Calculations:

pressure drops, heat transfer. Design

basis report. Process

and equipment design reviews |

|||||||||||||||||||||

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||