|

|

|||||||||||||||||||||||||

|

Chemical and Process Engineering |

|||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||

|

Energy from Waste (Gasification) |

|||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||

|

Project Background |

|

|

|

|

Client: Planet Advantage Limited |

||||||||||||||||||||

|

|

|

||||||||||||||||||||||||

|

Jessup-Bould

Limited provided technical support to Planet Advantage Limited during the pre-design

phases of this project which uses Enerwaste

technology. The plant has now been constructed at Scotgen’s

Dargavel site in Dumfries, Scotland. |

|||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||

|

Process Description |

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||

|

The plant is comprised of 2 waste

processing and heat recovery streams with a common steam turbine driven

alternator. Each stream has four gasification chambers

sequenced to operating on a programmed cyclic basis and provide a constant

flow of synthesis gas to a common (one per stream) oxidation chamber. When a gasification chamber becomes

available the operator opens the hydraulically driven front and rear doors. The

operator de-ashes the chamber by use of a front end loader with pusher tool

onto the de-ashing conveyor at the rear of the

chamber. When the

chamber has been emptied, the operator closes the doors. |

|

|

|||||||||||||||||||||||

|

To

charge the gasification chamber, the operator opens the hydraulically driven

charge door in the roof of the chamber. The front end loader is used to charge

the chamber with feedstock material. A top side operator monitors filling and

advises the front end loader driver as required to achieve an even

distribution in the chamber to the working level. On

completion of charging, the operator closes the charge door. The

operator initiates the chamber start up sequence. Provided that the

temperature in the oxidation chamber is above the minimum required by WID

(the Waste Incineration Directive), the sequence ignites the material in the

gasification chamber using the gas oil fired burner. Flue

gas generated during start up to flow through the refractory lined syngas

duct to the oxidation chamber. |

|||||||||||||||||||||||||

|

Once

combustion of the feedstock has been established oil firing is terminated and

the chamber undergoes sub-stoichiometric gasification. The resulting

synthesis gas flows through the established route to the oxidation chamber. A

temperature controller in the outlet duct from the chamber will vary the

speed of the chamber’s dedicated gasification air fan to control the

gasification reaction. Air for the process is drawn from within the process

hall. Waste heat is recovered from the

oxidation chamber flue gases by raising steam in a boiler. This steam is used

in the common turbine alternator to generate electricity for house use and

export to the grid. Condensate is recovered for reuse as

boiler feed water. Flue gas leaving the boiler is

cleaned by dry scrubbing with PAC / Sodium Bicarbonate and a bag filter. Continuous emissions monitoring is

used to control to Sodium Bicarbonate dosing rate and to ensure that the

plant meets regulatory requirements. |

Courtesy

of Enerwaste |

||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||

|

Responsibilities |

|

||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||

|

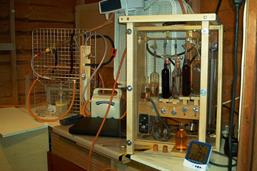

Technical

discussions with prospective detailed engineering design contractors. Mass end energy balance

verification (including site performance testing): Supply and

modification of laboratory equipment for gas sampling. Gas sampling and analysis for mass and energy balance purposes. |

|

||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||

|

The initial

contribution to this project was the assessment of the nominated detailed

design contractor. This mainly centred on resolving discrepancies in the mass

and energy balances provided by the technology provider and those from the

contractor. Although the contractor had undertaken gas sampling at a

demonstration plant for batch-wise processing of waste in Iceland, they were

not able to ascertain sufficient information to enable these data to be used

for mass balance purposes. Subsequently JBL was commissioned to undertake

another set of measurements. In the original set

of tests, the contractor had arranged for around ten gas samples to be sent

to the UK for analysis. Analysis in the UK was deemed necessary due to the

lack of gas analysis facilities in Iceland. This was reported to have been an

expensive exercise. As a result, JBL undertook on-site gas sampling and

analysis using an Orsat apparatus procured by Planet

and therefore available for their future use. The Orsat was deployed at site following a period of in-house

training with a tailor made gas ‘cocktail’ and equipment modification in the

UK. Training had shown that accurate results for CO, H2, CO2,

O2 and CH4 could be consistently achieved with the modified

apparatus. The availability of

analysis ‘on-demand’ more than tripled the number of readings taken at the

initial testing. Furthermore, a structured sampling and data logging

procedure was prepared that enabled meaningful data to be acquired in order

to derive a series of mass balances for each batch gasified.

Although the demonstration plant had no other means of monitoring energy

generated from the waste, these performance tests enabled the energy release

rate to be calculated using mass balance results. Issues over this

contractors quoted scope of supply meant that an alternative contractor was

sought. JBL assisted with the technical assessment of Planet Advantages

alternative contractors’ short list. Following

appointment of the detailed design contractor, there followed a transitional

period during which the findings of the site tests were reported and handed

over for use in the detailed design. |

|||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||

|

Unit Operations Batch

gasification chambers. Combustion. Fans. Boilers. Steam

turbine / Condenser Dry

flue gas scrubbing. Cooling

tower. |

Hazards

(Site testing) Waste;

combustible and pathogenic solids. Fuels

(gas oil). Gases

arising from process (CH4, CO, H2). Hazardous

analytical reagents (Conc. H2SO4, KOH, NaOH,

etc). Hot

gases, surfaces and materials. Moving

heavy plant. Rotating

machinery. Liaison Prospective

Detailed Process Design Contractors |

||||||||||||||||||||||||

|

|

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||