|

|

|||||||||||||||||||||||||||||

|

Chemical and Process Engineering |

|||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||

|

|

|

|

|

|

|||||||||||||||||||||||||

|

Huntsman LDPE

Project |

|||||||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

Low Density Polyethylene |

|

|

|

Client: Simon-Carves |

|||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||

|

2005/6 |

Senior Process Engineer |

||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||

|

Project

Background |

|||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||

|

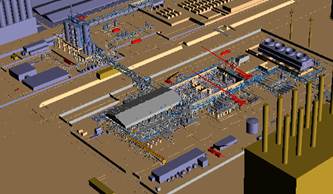

SembCorp

Simon-Carves Limited were initially awarded a contract by Huntsman

Petrochemicals UK Ltd (now Sabic), for the front

end engineering design (FEED) of the LDPE process using ExxonMobil’s

technology, They were subsequently awarded a further contract for the

detailed design, supply and construction of this plant at their Wilton

complex in the North East of England. This is the world’s largest single stream LDPE plant, with a total capacity of 400,000 tonnes per year. |

|||||||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

|||||||||||||||||||||||||||

|

Summary

of Process |

|||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||

|

The process (from ExxonMobil) is based on a high pressure tubular reactor. Ethylene is supplied to the plant and compressed using primary and secondary compressors to a pressure of around 3000 bar. |

|||||||||||||||||||||||||||||

|

|

|

|

|

||||||||||||||||||||||||||

|

Courtesy Simon-Carves |

|

The compressed Ethylene gas is preheated and

passed through a number of tubular reactor zones (total length nearly 3km) into

which organic peroxides, dissolved in a straight chain saturated hydrocarbon,

are injected to initiate the reaction. An unsaturated hydrocarbon can be added to the

ethylene as a modifier to control the melt index. An organic aldehyde can

also be used as a modifier for the production of medium density polyethylene. The reactors are double pipe units with

pressurised hot water flowing in the annuli. The polymerisation reaction is

highly exothermal and the energy removed from the reaction is converted in to

steam at various pressures for use within the LDPE plant and elsewhere on

complex. Excess unused ethylene is separated after the reactors and recycled

to the reactor feed system. The polymer melt is mixed with master-batch additives in an extruder to yield the final product. Some ethylene is carried forward through the extruder and the pellets are degassed with air during intermediate storage prior to being sent to final product storage. |

|||||||||||||||||||||||||||

|

|

|

|

|

||||||||||||||||||||||||||

|

|

|

|

|||||||||||||||||||||||||||

|

Specific

Responsibilities |

|

|

|||||||||||||||||||||||||||

|

|

|

|

|||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

Pressurised Water System |

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

The

purpose of pressurised hot water system is initially to bring the reactor metalwork

up to running temperature and then to remove the immense quantity of heat

generated by the reaction (c 50MW). The system also allows controlled

de-fouling of the reactors. The high operating temperature of the process

requires the water to be pressurised to around 30 barg

to avoid vaporisation occurring especially at the hot reactor walls. This required the specification of pumps, heat exchangers, control valves etc serving 6 reactor reaction zones and associated cooling zones, recycle gas cooling and as well as extrusion temperature control. A 50 m3 expansion drum also formed part of this system. |

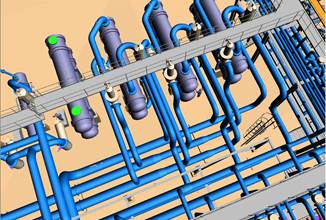

Courtesy Simon-Carves |

||||||||||||||||||||||||||||

|

Utility Systems |

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

|||||||||||||||||||||||||||

|

The

detailed design of the utility systems covered steam, condensate, cooling

tower water distribution, raw and process water, plant and instrument air,

high and low pressure nitrogen, boiler feed water and silo wash water

systems. For use

within the plant, imported steam (up to 65 barg)

from the Wilton power station is let down to high pressure (32 barg) using enthalpy control. The pressure is then

subsequently let down to medium (10 barg) and low

(3.5 barg) pressures. Condensate

from these systems is recovered at different pressures to minimise the amount

of flash steam formed in the condensate pipe work. The plant

also has steam and condensate switching station to allow the use of either MP

or LP steam for jacketing and tracing. For

operations that produce excess steam, a direct contact condenser was

specified, with the resulting condensate being used as cooling tower make-up

water. The boiler

feed water system required the specification of de-aerator and boiler feed

water pumps. After de-aeration of recovered condensate together with

demineralised water imported from the power station, it is chemically treated

for use in process waste-heat boilers, steam de-super-heaters and for make-up

to closed circuit water systems. Liaison

with the plant Owner was required in relation to battery limit and water

treatment requirements. |

|||||||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

Documents Produced Process

descriptions. Utility demands. P&IDs Control system

narratives. Process calculations

and data sheets for centrifugal and reciprocating pumps, shell and tube heat

exchangers, pressure vessels. Specialist Software "InTools" for creating process specifications for

instrumentation. "PDMS Reality

Review" for 3D plant layout visualisation. "TASC5"

for shell and tube heat exchanger design. |

Instrument data

sheets for pressure, temperature, flow and level transmitters. Specifications for

steam pressure reducing and de-super-heating stations. Calculations in

support of instrument and pressure regulator specifications. Calculations for

pressure drop, line sizing and control valve size checks. Process duty steam trap specifications. |

||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||